Applications

Foam is a versatile and durable material used by IFG for a variety of professional applications. From the medical world to the offshore industry, and from packaging to insulation solutions; IFG combines specialist knowledge with advanced techniques to deliver products that meet the highest standards. Thanks to foam’s unique properties, such as flexibility, light weight, durability and value for money, we can create customized solutions for every conceivable project.

Medical applications

Foam plays an important role in the medical sector, where comfort, hygiene and precision are vital. IFG develops hypoallergenic, water-repellent and biologically compatible foam products that meet the strictest standards. From positioning systems and cushions to medical devices, our products are customized to contribute to patient care.

Packaging

In the packaging industry, foam is proving its worth as a flexible, reusable and durable material. IFG supplies high-quality interiors for cases, protective packaging for transportation and even special filters and displays. Whether for single-use or luxury presentation, we offer packaging solutions that perfectly suit your needs.

Insulation

IFG develops foam products that provide optimal insulation in industrial applications. From sound absorbing panels and thermal insulation to protective buffers, our solutions improve acoustics, increase energy efficiency and protect equipment and people.

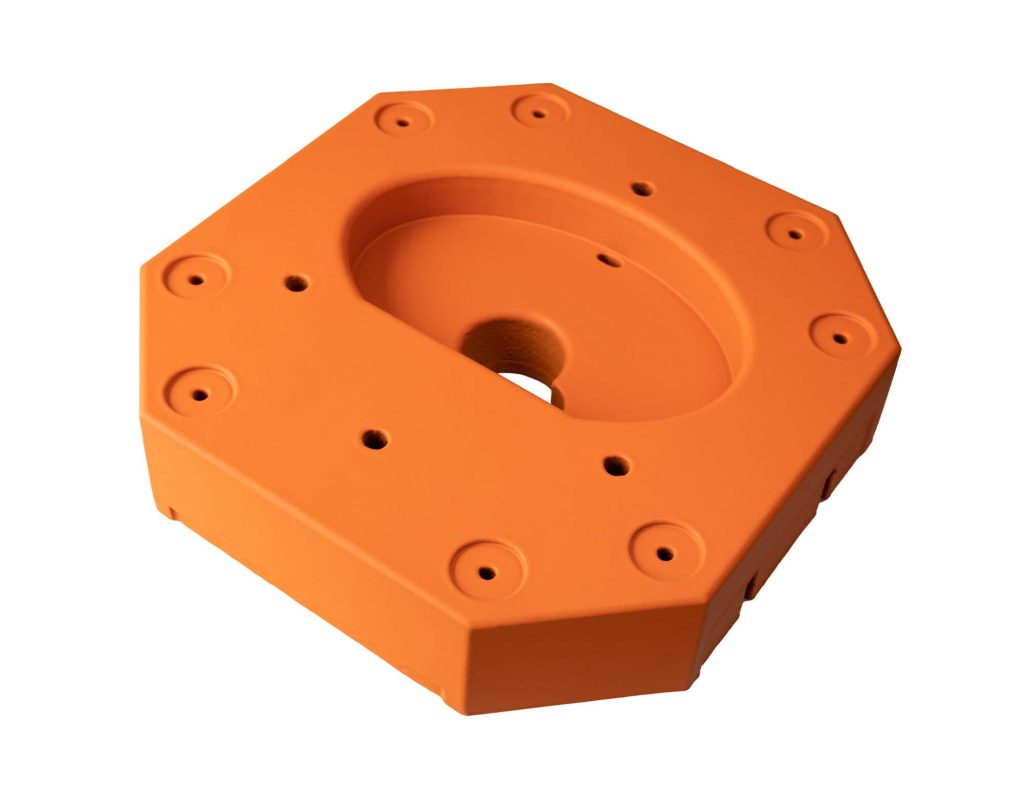

Offshore

In the packaging industry, foam is proving its worth as a flexible, reusable and durable material. IFG supplies high-quality interiors for cases, protective packaging for transportation and even special filters and displays. Whether for single-use or luxury presentation, we offer packaging solutions that perfectly suit your needs.

Furniture & Interior

Foam is a versatile material that combines design freedom, comfort, and functionality—making it an integral part of the furniture and interior world. IFG supplies custom foam solutions for furniture manufacturers, interior designers, and concept developers. We process and coat foam for a wide variety of applications, ranging from sculptural seating objects to industrial beanbags.

Construction

Foam is indispensable in construction, thanks to its excellent insulation, protection, acoustic properties, and design flexibility. It is used for applications such as air duct insulation, seam sealing, shock absorption, and acoustic panels, where robust foam types (such as PE) are combined with coatings for water and airtightness. In addition, flexible PU foam enables unique contours in interior elements. For technical precision and quality, our team offers direct advice and customized solutions.

Retail

Foam plays an important role in retail: it protects products, ensures a clean presentation, and strengthens the overall brand experience. IFG develops custom foam solutions for displays, luxury packaging, and high-end product presentations. Whether it concerns jewelry, cosmetics, or POS displays, foam allows you to combine aesthetics, durability, and efficiency—with less damage and maximum visual impact on the shelf.

Industrial damping

Foam plays a crucial role in controlling noise and vibrations. IFG develops tailor-made foam solutions that reduce wear, increase reliability, and improve comfort. From machine-filled workspaces to call centers, our foam ensures quiet, durable, and efficient performance in any industrial environment.

Care & comfort

Foam is essential in care and comfort applications because it distributes pressure evenly, supports body shapes, and provides long-lasting comfort. It is used for seating and lying support, positioning cushions, and changing pads, where hygiene, shape retention, and customization are key. With a wide range of foam types and hygienic coatings, we create solutions that are both safe and comfortable. Discover even more possibilities within these applications.

Customization for each project

Is your sector or application not listed here? At IFG, we are happy to think along with you. Our customized solutions offer virtually unlimited possibilities. Thanks to our advanced machinery and in-depth expertise, we develop products that fully meet your needs and specifications.

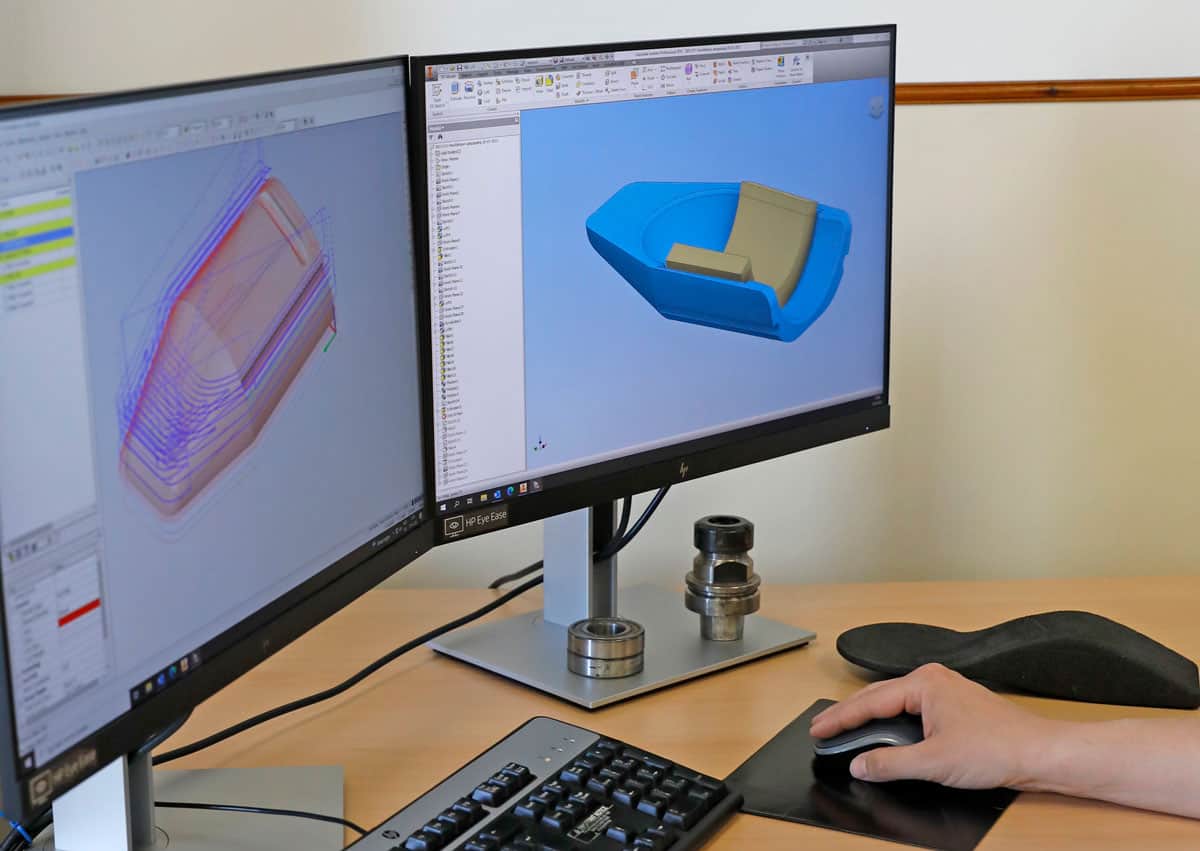

Our approach: from idea to final product

At IFG, we work closely with our clients to realize innovative solutions. We follow a structured process to bring each assignment to a successful conclusion:

- Idea / Concept: Together we develop a clear plan based on your needs.

- Product specification: We define the technical requirements and preconditions.

- Design: Our specialists translate your requirements into a detailed design.

- Prototype: We create a functional prototype for testing and feedback.

- Final Product: The final product is produced and delivered with care.

With this method of working, which meets the ISO 9001 standard, we guarantee reliability, quality and continuity in every project.

Get in touch

Want to learn more about our applications or discuss a specific solution? Contact our specialists without obligation. Together we will find the perfect solution for your project.