Furniture & Interior

Foam solutions for furniture and interior applications

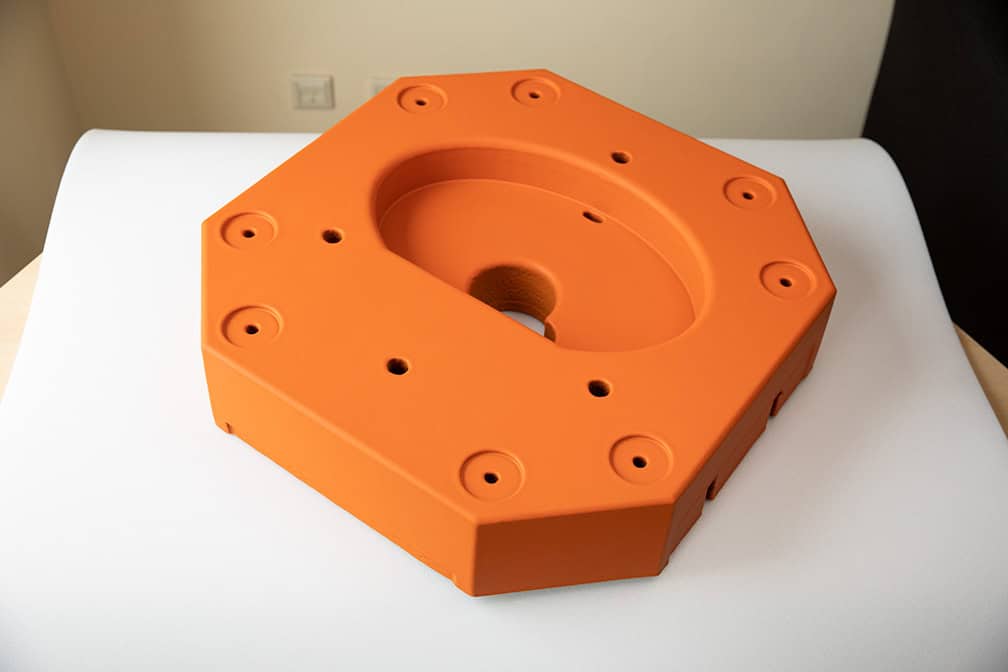

Foam is a versatile material that combines design freedom, comfort, and functionality. In the world of furniture and interiors, it is indispensable. IFG provides custom foam solutions for furniture manufacturers, interior designers, and concept developers. We process and coat foam for a wide range of applications: from sculptural seating to industrial beanbags.

In-house foam production and coating

Our strength lies in processing and finishing foam entirely in-house. Upholstery or other constructions are handled by the client or external parties. IFG delivers the technically high-quality foam component: precisely cut, optionally coated, and ready for integration into a piece of furniture or interior application.

Formable and lightweight foam for furniture design

Foam allows designers to create bold shapes that are difficult or costly to achieve with traditional materials. Thanks to its low weight and ease of processing, furniture can be both striking and durable. Examples include round poufs, modular seating, children’s furniture, or relief wall objects.

Because foam can be processed seamlessly, it is ideal for design projects where form and finish merge. Designers from Belgium and Germany are already using our materials to create unique series of seating and objects.

Coated foam: finish for aesthetics and functionality

At IFG, we apply coatings to foam that are both decorative and protective. Coatings provide a smooth, low-maintenance finish and are available in various colors and textures, including matte or glossy finishes, metallic looks, or concrete-like textures.

The coating layer enhances durability and makes the foam suitable for intensive use, such as in hospitality, retail, or public spaces. In some cases, the coating also contributes to fire-retardant or hygienic properties. More information can be found on our coatings page.

Foam for outdoor furniture and weather-resistant applications

Foam is not only suitable for interior applications but also performs well outdoors. With specific foam types and protective coatings, products remain shape-stable, water-repellent, and UV-resistant, even with prolonged exposure to rain, sunlight, or temperature fluctuations. Examples include:

- Outdoor benches and seating for terraces, hotels, and sports fields

- Children’s furniture for playgrounds or schoolyards

- Modular elements for recreation and events

The coating provides a protective layer that shields the foam from moisture and dirt. This makes the furniture weather-resistant and easy to clean. Combined with PE foam or coated PU foam, it creates a lightweight, durable product suitable for outdoor use without shelter.

From design to production: collaboration with designers and manufacturers

We supply custom-cut foam blocks, panels, or shapes that serve as the basis for benches, poufs, lounge furniture, or objects. The client then handles upholstery or integration into a structure. This approach aligns with our vision of customization and co-makership: collaborating from the design phase with short lines of communication and technical expertise.

A concrete example is our collaboration with G-Star’s interior partner: for their new stores, we supplied square poufs (45 x 45 x 45 cm) with a special aluminum-look coating. These pieces are both functional and aesthetically distinctive.

Design cases & applications of coated foam in furniture

The possibilities are wide-ranging:

- Free-standing seating objects such as poufs or cubes

- Children’s furniture and lounge elements

- Retail displays or sculptural showpieces

- Soft wall panels or stacked forms

- Outdoor furniture and weather-resistant applications

Sustainable and circular: beanbags with flake filling

At IFG, we think circular. Leftover material from cutting processes is shredded into flakes. These high-quality flakes are used as filling for beanbags or cushions with an industrial look. This extends the material’s lifespan and prevents waste.

If leftover foam is unsuitable as flake filling, we still recycle it. More about our sustainable approach can be found on our recycling page.

Applicability of ISO standard 10993 to our coatings

Our coatings for medical products are designed to be hypoallergenic and biocompatible, releasing no harmful substances and safe for direct skin contact. Extensive testing in international laboratories has shown that the coatings comply with ISO standard 10993, ensuring reliability and safety for medical applications.

Foam types and processing techniques

We work with different types of foam, tailored to the desired properties:

- PU polyether foam: soft, breathable, ideal for comfort and freeform designs

- PU polyester foam: shape-stable, suitable for coating and decorative finishes

- PE foam: firm, for structural or shape-retaining applications

Our foams are custom-cut, milled, glued, and coated, all under one roof.