Industrial damping

Industrial damping focuses on controlling noise and vibrations in machines, installations and buildings. With the right foam, you reduce wear, increase reliability and improve comfort for employees. Industrial damping is not a standard product but a tailored solution that we adapt precisely to your application, environment and requirements.

Foam as a solution for industrial damping

Industrial processes require reliable materials that control peak loads, resonances and structure-borne noise. Specially developed sound-absorbing foam absorbs noise without adding much weight. Typical applications include industrial sound damping around fans, compressors and transport systems. The material is dimensionally stable, low-emission and suitable for series production, making industrial damping both effective and economical.

Advantages of foam for industrial damping

- Durable: recyclable material and long service life

- Efficient: high damping performance with minimal volume and weight

- Clean and safe: low dust emission and free from harmful substances

Intermediate foam layers for component protection

Sensitive components can be damaged by vibrations and impacts. Foam for component protection absorbs these shocks, keeping everything firmly in place and immediately reducing structure-borne noise. Custom foam inlays provide exactly the right support and protection.

Vibration damping in industrial applications

Vibrations often cause malfunctions or loose components. Vibration damping foam absorbs these vibrations without the need for heavy springs or rubber blocks. Applying foam in the right places keeps the structure stable and predictable.

Foam for electronic enclosures

Electronics must be well protected against noise and vibrations. Damping gaskets and foam for electronics seal joints, dampen resonances and ensure stable installation. Acoustic foam in housings prevents whistling noises and unwanted echoes. PU foam in industrial applications offers a uniform structure and wide design possibilities.

Sound-absorbing inlays in cabinets or pump units

Typical applications

- Pump units, compressors, fans and drives

- Control panels and enclosures

- Logistics cabinets and production machinery

Acoustic applications in work environments

Foam types and finishes

For each project, we select the material based on load, environment and service life. PU foam for industrial applications offers a wide range of densities and stiffness levels. Polyester foam performs well in airborne sound absorption and dimensional stability, while polyether foam often performs better in humid environments. At IFG, you will find industrial damping solutions that balance absorption, insulation and buffering.

Common choices:

- Sound-absorbing foam with open-cell structure for enclosures and ducts

- Vibration damping foam with controlled spring constant for machine bases

- Sound-absorbing inlays with washable top layers for hygienic sectors

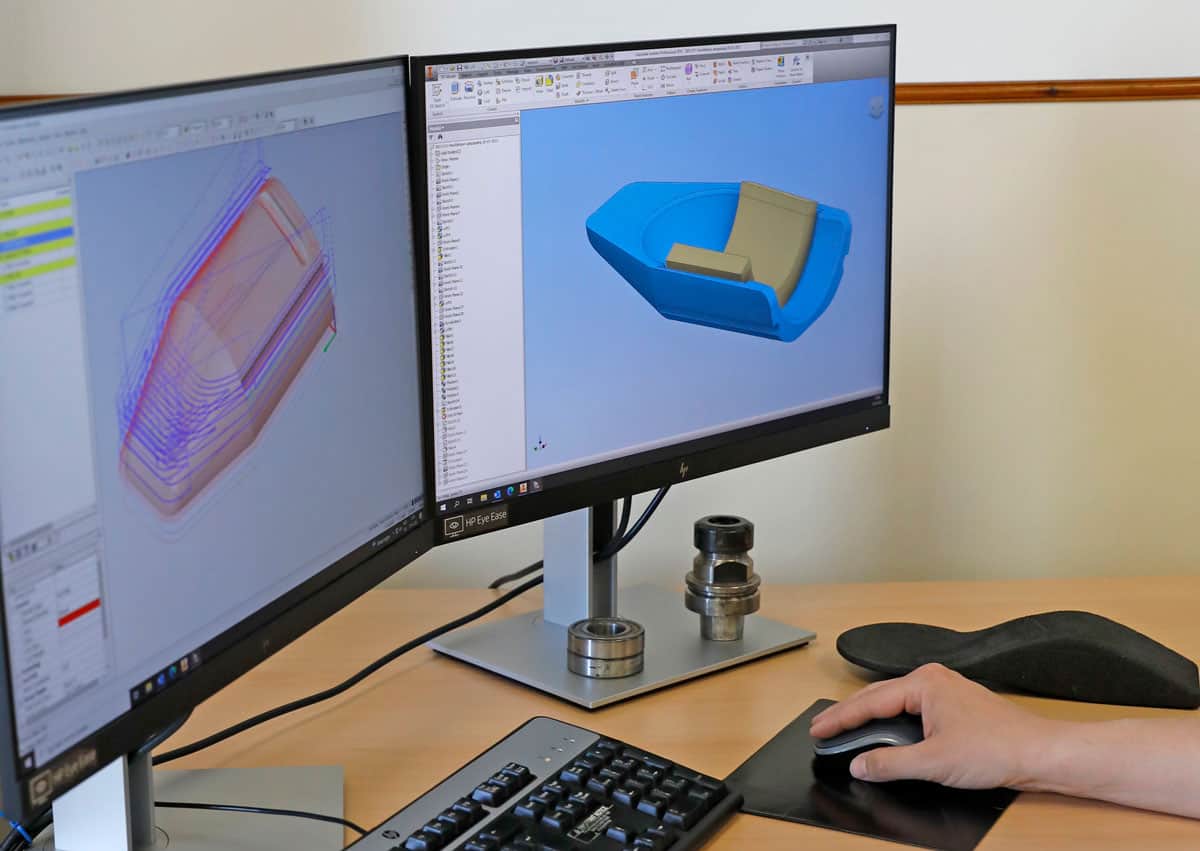

Custom solutions and collaboration for damping foam

Every machine and enclosure requires a unique solution. With custom damping foam, we design shapes and thicknesses that fit perfectly. Prototypes are quickly tested in your setup, ensuring that noise and vibration damping with foam works in practice. We think along with you and provide solutions that remain easy to service.

More information about foam solutions for industrial damping

Do you need advice on material selection or finishing? We support you from concept to series production and provide samples, measurement reports and clear specifications. This ensures industrial damping that demonstrably works and is easy to install. Our recyclable materials provide a quiet and sustainable solution with a long service life.

Contact us directly for tailored advice or request a no-obligation quote. We respond quickly with a practical proposal and clear lead times.