Packaging

Fragile products require packaging that protects against shocks, pressure, and movement. IFG develops and produces custom foam solutions for packaging across various sectors. For the protection of electronics, machine parts, tools, measuring instruments, displays, and luxury consumer goods, the right packaging foam ensures your product remains safe, stable, and attractively packaged.

Our foams are not only functional but also sustainable. Thanks to their low weight, long lifespan, and recyclability, they contribute to efficient logistics and a responsible choice of materials. Read more about our focus on sustainability and recycling.

Applications and benefits of packaging foam

Packaging foam offers a range of advantages. Its low weight reduces transportation costs. The precise structure and cushioning properties of foam make it ideal for protecting sensitive contents. Our foams are also easy to shape into any desired form and are reusable and recyclable.

Foam is used in packaging in many ways:

- Inlays for transport cases and flight cases: custom-fit inlays keep fragile equipment securely in place during transport.

- Electronics and measuring instruments: shock-absorbing layers absorb vibrations and prevent damage.

- Presentation inlays for cosmetics or luxury goods: combine aesthetics and protection.

- Industrial applications: interlayers and stacking inserts ensure products can be safely stacked and moved.

Would you like to know more about the types of foam we use for these applications? Visit our pages on PU polyether foam, PU polyester foam, or PE polyethylene foam.

Disposable packaging: 100% recyclable

Do you need disposable packaging that is 100% recyclable? We can provide that. Recyclable disposable packaging offers a practical and environmentally friendly alternative because it can be reused without complex pretreatment.

Custom packaging foam solutions for different sectors

The right packaging solution starts with a thorough understanding of the product and industry. For technical components and machine parts, we provide foam solutions that match the product’s weight, size, and sensitivity. Medical equipment often requires soft, hygienic, and shape-retaining foam for the healthcare sector. Retail packaging for cosmetics or gifts demands foam that is both stylish and protective. For industrial products that are vulnerable during transport or storage, we create functional and efficient protective layers.

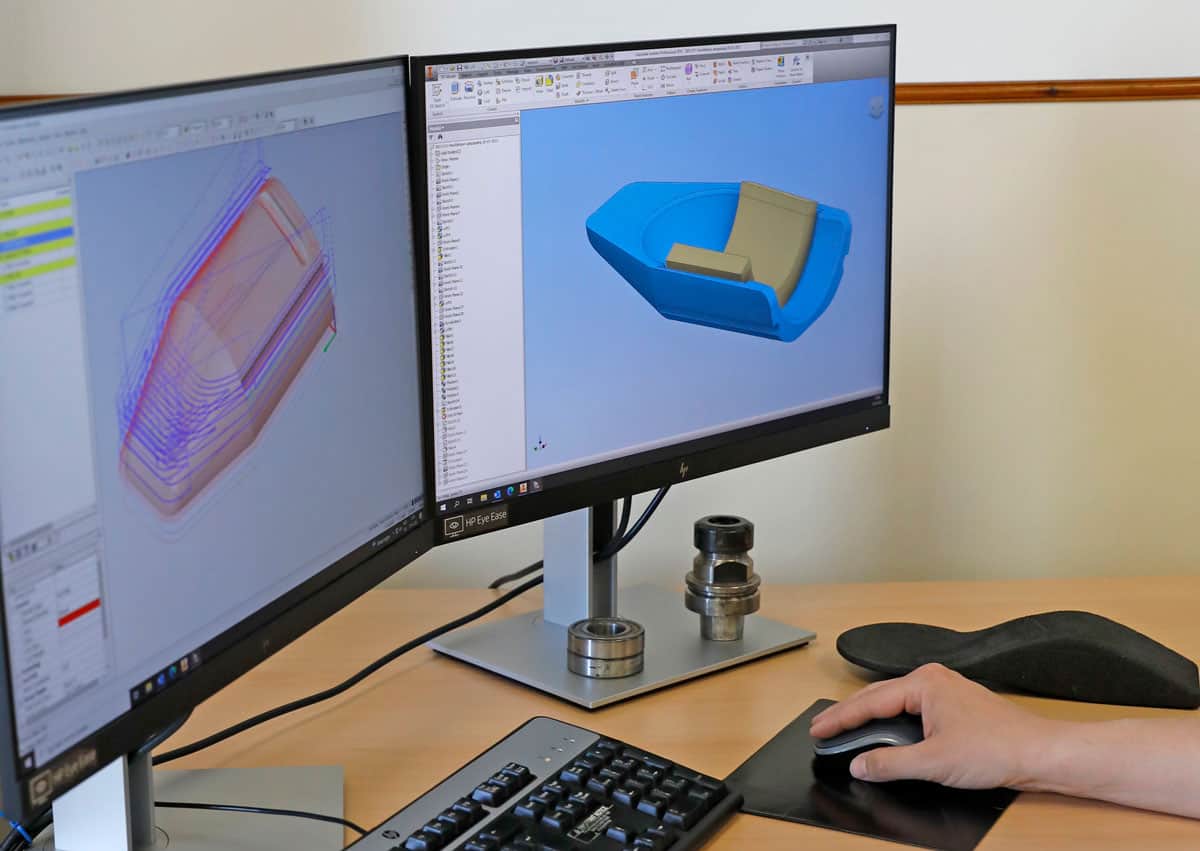

Packaging solutions and co-makership

All of this is achieved through co-makership: jointly developing packaging solutions in close collaboration with our clients. We actively contribute from the first idea, carefully assess the application, and advise on the right combination of foam type, shape, and processing. By getting involved early in the development process, we can optimize packaging concepts for protection, cost, and manufacturability. This partnership not only results in a better end product but also in a more efficient process and a more sustainable outcome.

Interlayers and cushioning elements in packaging

A stable interlayer prevents damage and ensures efficient use of packaging space. We provide foam sheets and filler plates used as cushioning between stacked products or as protective elements within packaging. These solutions are often used in reusable packaging systems or industrial trays.

Thanks to our experience in custom production, we can deliver flexibly, from prototypes to large production series, fully customized and tailored to your logistical requirements.

Custom packaging foam: material and processing

Depending on the level of protection and type of packaging required, IFG selects the appropriate foam material. PU foams are ideal for soft, resilient applications where the foam conforms to the product. PE foams are firm, durable, and have a closed-cell structure, providing good insulation and mechanical strength. For electronics applications, antistatic foams are also available, and for higher safety requirements, flame-retardant foam is the right choice.

All processing is done in-house. We cut, mill, and punch foam into the desired shape. Bonding and lamination with other materials is also possible. For extra protection, see our coatings page for available finishes.

Coatings for packaging foam

For specific applications within the packaging industry, our foams can be provided with functional coatings. This is particularly useful in environments where products are sensitive to electrostatic discharge (ESD) or where additional protection from external influences is required. For example, we can make foam surfaces antistatic, making them safe for packaging electronic components. Conductive coatings are also possible, for example when products need to be grounded during transport.

Additionally, coatings are available that make foam more resistant to oil, moisture, or chemicals. This is particularly relevant in industrial logistics, where durability and reuse are important. By combining the right foam base with a functional coating, a packaging solution is created that protects, performs, and lasts longer.

Why choose IFG for your packaging foam?