Coatings

Processing and finishing foam

The processing and finishing of foam is an essential step to fully utilize the unique properties of this versatile material. Coatings play a vital role in this process: they determine the functionality, quality, and durability of the final product. At IFG, we combine innovative techniques and tailored solutions to provide foam products with coatings that meet the highest standards.

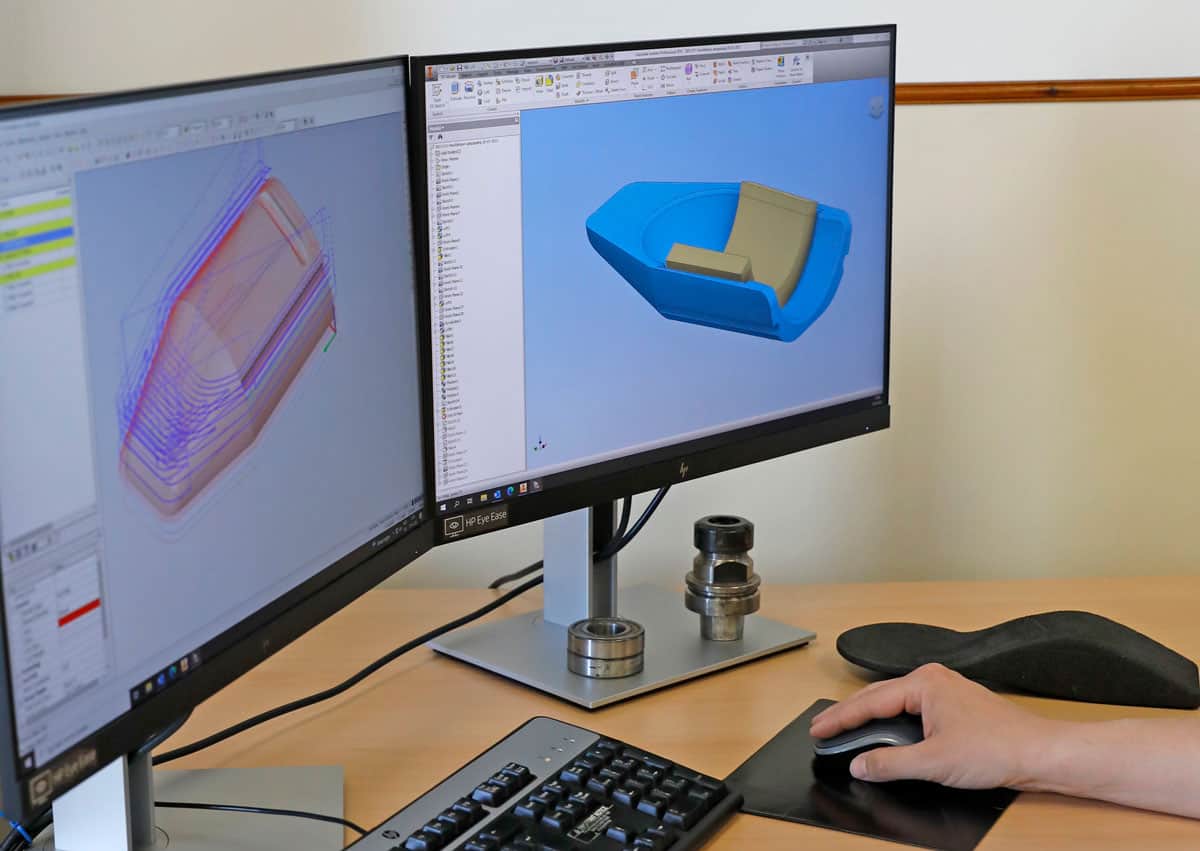

What makes our coating special?

Our coatings are developed entirely in-house, allowing us to precisely tailor each layer to the product’s specific requirements. Through innovation and precision, we ensure that the coating not only provides protection but also significantly enhances the foam’s performance.

- Hygiene and safety: Specially developed coatings are biologically compatible, making them safe for direct skin contact. This is crucial for medical applications such as patient positioning systems.

- Durability: Whether for industrial applications or designer furniture, our coatings significantly extend the product’s lifespan.

- Functional enhancements: Waterproofing, breathability, rigidity, or flexibility—whatever your application requires, we deliver custom features.

Our coating options

Breathable and water-repellent coating: This coating combines breathability with water-repellent properties, making it ideal for medical positioning cushions. It is suitable for cleaning with alcohol solutions (up to 70%) or non-corrosive cleaning agents and is commonly used in medical examinations and disinfectable surfaces.

Airtight and waterproof coating: Robust and perfect for cushions providing full body support during medical procedures, this coating is often combined with core materials like closed-cell foams (PE or PU). It offers durability and excellent cleaning capabilities.

Hard coating: A two-component PU coating designed for demanding environments, it enhances the mechanical strength of products. Applications include offshore and industrial solutions such as fenders, buoys, floaters, and transport cases. It withstands intensive use and heavy impacts.

Soft coating: Durable, comfortable, and versatile, this coating is suitable for both indoor and outdoor applications. It is used in (designer) furniture and industrial products, offering strength and rigidity combined with comfort.

Why choose IFG?

IFG stands out for its innovation and customization. We don’t view coatings as merely protective layers but as integral components of a product’s properties. By managing every aspect of the coating process in-house, we ensure not only precision but also a final product that perfectly aligns with the application’s requirements. Whether it’s a medical device, industrial part, or aesthetic design object, IFG provides solutions that go beyond the standard.

Get in touch

Are you looking for a specific coating solution or want to learn how IFG can enhance your product? Contact us today and discover how we can translate your ideas into high-quality, durable, and functional foam products.