Co-makership

Collaborating on innovative solutions, that's co-makership at IFG.

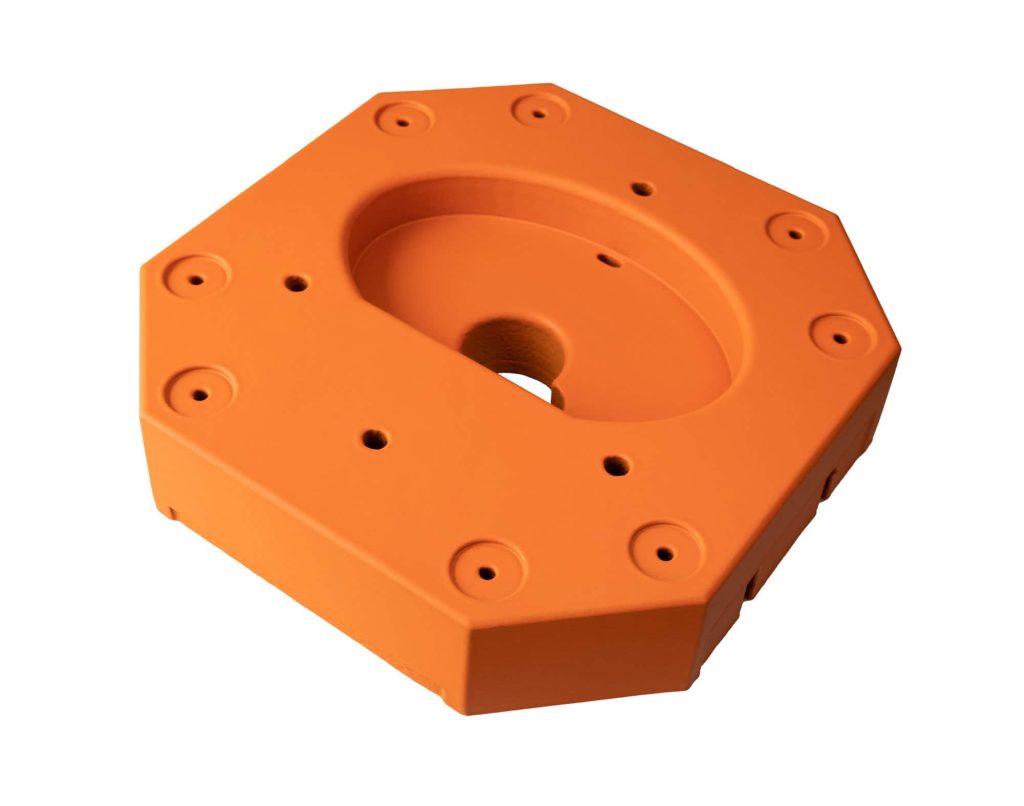

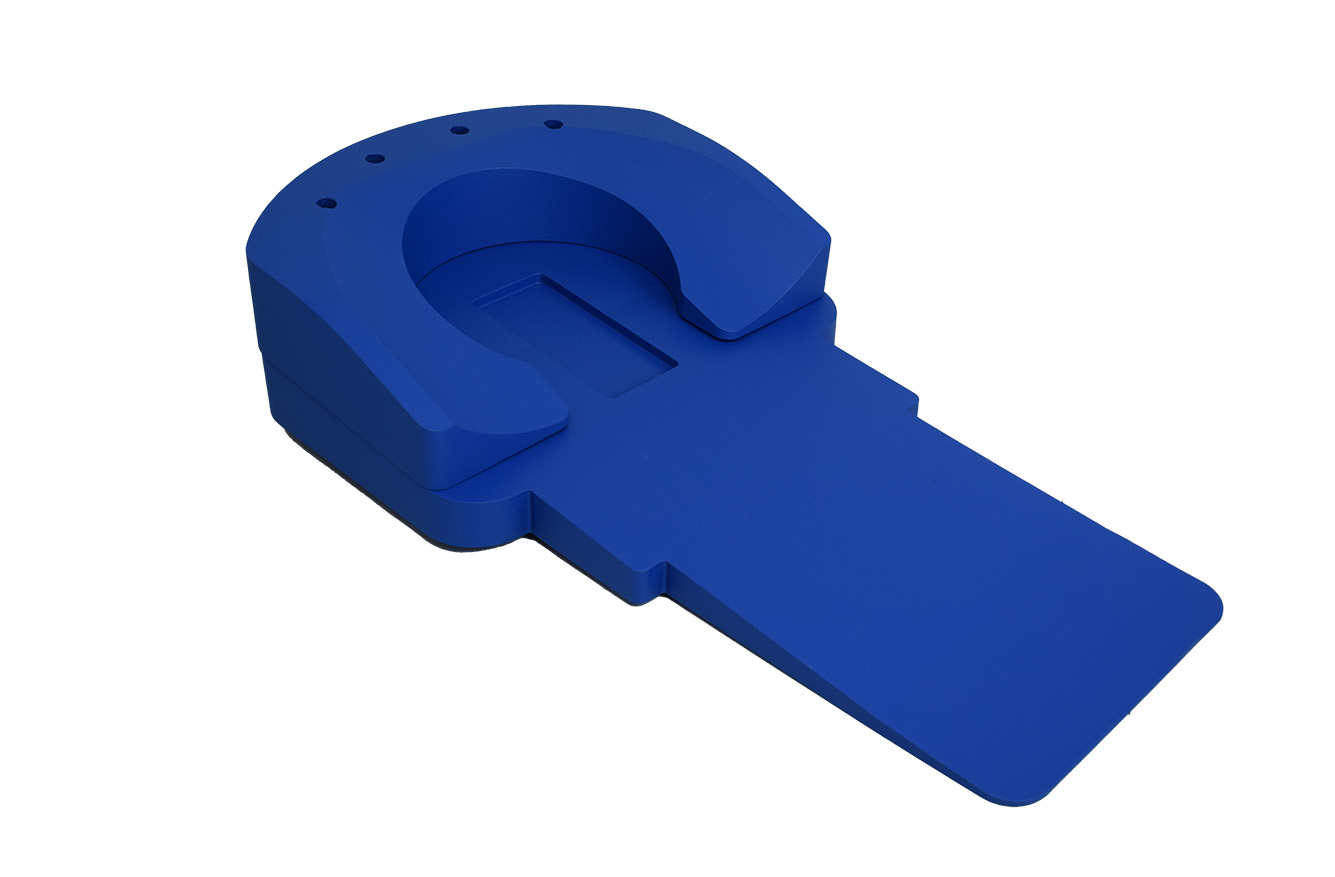

At IFG, we believe in the power of collaboration. Many of our clients have an existing product, device, or machine that requires a specific coating. Instead of offering a standard solution, we develop this coating together with the customer. The same applies to other foam products.

This co-makership ensures a solution that perfectly meets the technical requirements and usage conditions.

Wat is Co-makership?

Co-makership is een werkwijze waarbij IFG en de klant samenwerken als partners. Onze engineers staan zij aan zij met uw specialisten om uitdagingen vanuit verschillende invalshoeken te benaderen. Samen zetten we ideeën om in concrete, haalbare oplossingen. In dit proces staat wederzijds vertrouwen centraal: wij luisteren naar uw inzichten en delen onze expertise, zodat we gezamenlijk de beste resultaten kunnen realiseren.

From Idea to Market Introduction

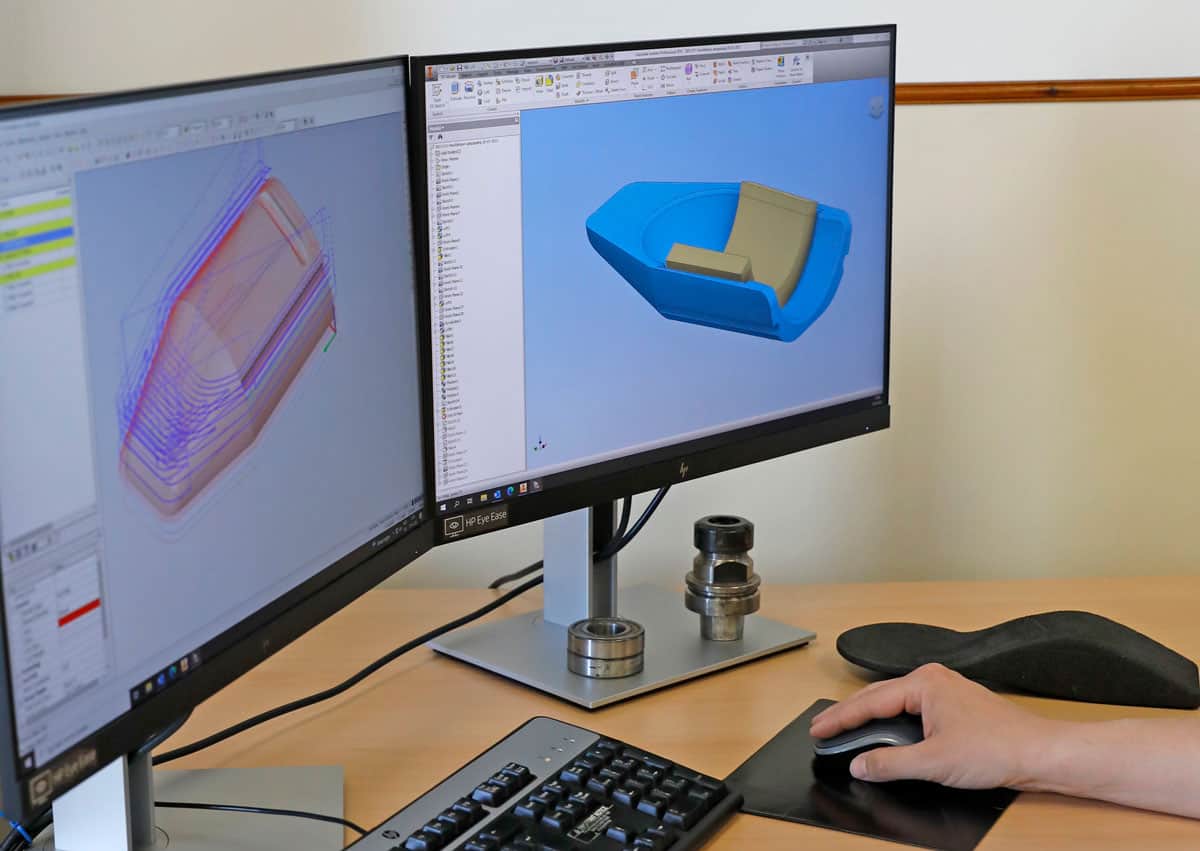

Collaboration with IFG follows a structured process in which innovation, customization, and quality are at the core.

Our Approach:

- Requirements Package:

In consultation with the client, we create a detailed requirements package. This document outlines all functional and technical specifications, such as protection, wear resistance, and material selection. - Drawings with Possible Solutions:

Based on the established requirements, we develop initial sketches and technical drawings. These visualize potential solutions and provide a foundation for further alignment. - Talk Document and Prototype:

We translate the drawings into a concrete proposal, supported by a prototype. This talk document helps to refine and optimize the solution with the client before production begins. - Pricing: Based on the final design, we provide a price estimate, taking into account material costs, production time, and any adjustments at a later stage.

- Pilot Phase: Before large-scale application, we start with a pilot phase. This initial trial production helps to test whether the coating meets all requirements.

- Pilot Series: After a successful pilot, we produce a small batch for the client to test the application in a real-world environment.

- Market Try-Out: The pilot series is tested in practice with a select group of users. This provides valuable feedback on the performance and durability of the coating. Changes and

- Optimizations: Based on the test results, further adjustments can be made to refine the solution.

- Final Pricing: Once all optimizations have been implemented, we finalize the price. Market Introduction: The coating is now ready for broader application and is officially introduced to the market. Scaling and Modifications: If needed, we scale up production and implement any modifications so that the solution can be deployed on a larger scale.

IFG is your partner in co-makership.

At IFG, we don’t just work for our clients, but with them. Through co-makership, we can develop innovative, high-quality coatings that perfectly meet the specific needs of our clients. Want to know what IFG can do for your product? Get in touch with us and explore the possibilities!

A culture of innovation

Co-makership is more than just working together; it’s also a way to foster innovation. By combining our expertise with your insights, new possibilities emerge that were previously unimaginable. This not only leads to improved products but also to more efficient processes, lower costs, and a shorter time-to-market.

Why choose Co-makership with IFG?

- Expertise: Our engineers have extensive knowledge and experience across various industries.

- Efficiency: Short communication lines and direct feedback ensure a smooth process.

- Innovation: Together, we come up with creative solutions that truly make a difference.

- Customization: Every product is tailored to your specific needs and challenges.

- Reliability: We are fully committed to meeting our agreements and exceeding your expectations.

Contact our team

Are you ready to innovate with us and build a successful future? Get in touch with us today to discuss the possibilities of co-makership. Our specialists are ready to work together to realize the best solutions.

Together with IFG, you make a difference.