Recycling

From Waste Material to New Raw Material: A Circular Process

At IFG, we are committed to sustainability by efficiently recycling foam remnants and discarded products. During the production and processing of foam products, residual materials are left over. Instead of discarding these materials, we take them back and process them into new raw materials. This not only contributes to a circular economy but also helps our customers reduce costs and waste streams.

At IFG, we have everything in place to tackle this challenge. With a fully equipped machinery park and a wide range of specialized tools, we carry out every project entirely in-house. This ensures that we can guarantee not only flexibility and speed but also a tailor-made solution of the highest quality for every assignment.

How Does Our Foam Recycling Work?

Our recycling process is designed to efficiently utilize residual streams:

- Collection of remnants: Clean foam scraps left over after processing are collected by us. Customers abroad must contact us for this service.

- Convenient collection in large bags: The foam residues are collected in large bags left at the customer’s location. During a new delivery, the full bags are taken back in consultation with the customer. Thanks to our own transport, we can organize this efficiently for both IFG and our clients. For customers abroad, this only applies after coordination with the customer and is not a strict guarantee.

- Processing into new raw materials: We recycle these residual materials into various reusable raw materials such as granulate, wire mats, and hydro mats.

- Collection of discarded products: Provided they are not contaminated, we also take back discarded foam products so they can be reused in production.

- Efficient logistics: Since it's our own product, the return process is simple and cost-effective.

Savings on waste costs

Foam products are bulky, meaning they take up a lot of space during waste disposal. By using our recycling service, customers significantly save on waste removal costs. This makes recycling not only environmentally friendly but also economically attractive.

The difference between recycling and reuse

It is important to distinguish between recycling and reuse. Recycling means that foam remnants are reprocessed into raw materials and used again for the same applications. This is a completely circular process. Reuse, on the other hand, means that a product is used for a longer time, but eventually still becomes waste. Our recycling method ensures that the material’s life cycle is fully closed.

Suitable foam types for recycling

At IFG, we focus on recycling specific types of foam that are highly reusable. Polyethylene foam (PE) and polyurethane foam (PU) are among the materials suitable for our recycling process.

Polyethylene Foam (PE): This flexible and lightweight foam is highly recyclable. After use, it can be reclaimed and processed into new raw materials, contributing to a circular economy.

Polyurethane Foam (PU): PU foams, including both flexible and rigid variants, are also recyclable. Various methods have been developed to recycle PU foam, such as mechanical and chemical processes, enabling this material to be reused in a variety of applications.

PE Non-Crosslinked Packaging Foam vs. Cardboard: A More Sustainable Alternative

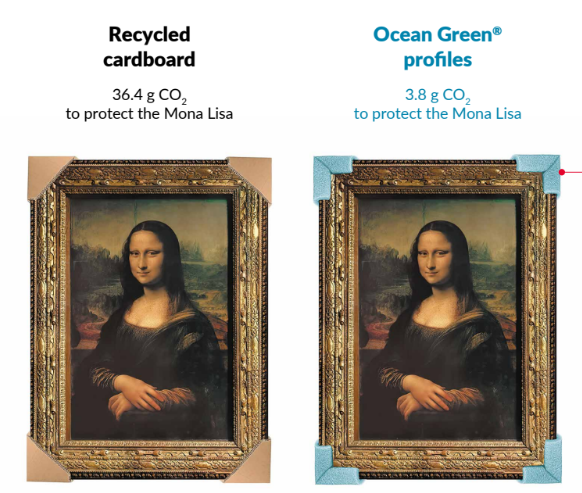

When it comes to packaging materials, it is often thought that cardboard is the most sustainable choice. However, PE non-crosslinked packaging foam* offers a significant environmental benefit over cardboard.

- Lower CO2 footprint: The production and processing of PE foam uses less energy and produces less CO2 emissions compared to cardboard.

- Lighter material: This results in lower emissions during transport and reduces costs.

- Longer lifespan: Unlike cardboard, which is often discarded after one use, PE foam can be recycled multiple times without quality loss.

Thanks to these advantages, PE non-crosslinked foam is not only a functional but also a more sustainable alternative to cardboard packaging.

PE non-crosslinked packaging foam is a flexible and lightweight material widely used for product protection during transport. Unlike chemically crosslinked foam, non-crosslinked PE foam retains its recyclability because it has not been chemically altered during production. As a result, it can be easily reprocessed and used for new applications.

Which companies benefit from our foam recycling?

Our recycling service is particularly suitable for companies that use foam packaging and protective materials on a large scale. This includes manufacturers of packaging solutions, producers of insulation materials, and companies in the construction and transport sectors that use foam applications for protection and damping. By using our recyclable foam, they not only benefit from high-quality and sustainable materials, but also from efficient waste management that reduces costs and environmental impact.

IFG is your partner in sustainable business.

At IFG, we believe that recycling is the key to a more sustainable future. By working together with our clients, we ensure that foam remnants are not wasted but play a valuable role in the production cycle once again. Would you like to learn more about our recycling options and how we can help you reduce your ecological footprint? Contact us today!