Custom made

Customization and Expertise in Foam Processing

Processing foam into the desired shapes and applications requires knowledge and advanced equipment. Foam processing and coating are complex procedures that demand precision and experience. Only with the right expertise and technology can the material be optimally adapted to specific requirements and designs.

At IFG, we have everything needed to take on this challenge. With a fully equipped machinery park and a wide range of specialized tools, we carry out every project entirely in-house. This means we can guarantee not only flexibility and speed but also a tailor-made solution of the highest quality for every assignment.

Innovative Techniques for Perfect Customization

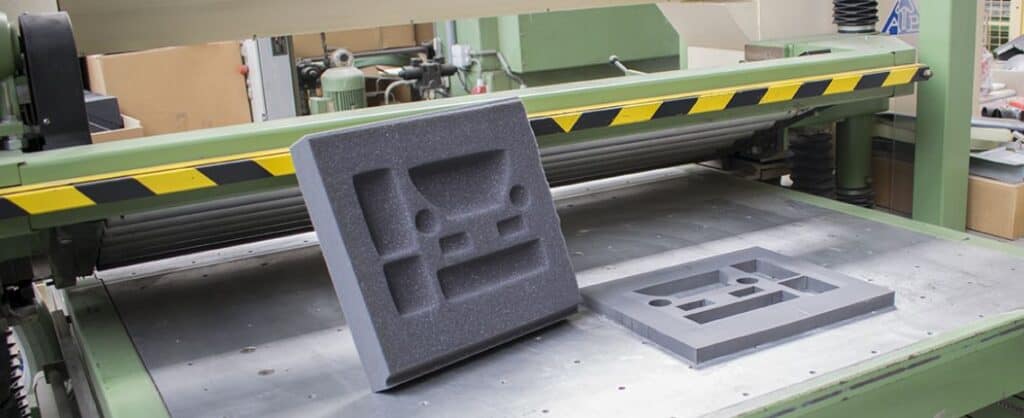

To process foam down to the finest details, IFG has an extensive machinery park. From hand tools for precise adjustments to state-of-the-art CNC-controlled machines capable of executing complex operations. Our flagship is the 5-axis CNC milling machine, which allows us to produce even the most advanced designs fully automatically and with extreme precision. This technology enables us to push boundaries, whether for simple shapes or intricate 3D structures.

In addition to CNC technology, our machinery park offers many other capabilities, including:

- Horizontal and vertical contour cutting for creating clean lines and complex contours.

- Shape cutting and profiling for unique designs and specialized applications.

- Laminating and die-cutting to combine different materials and ensure a high-quality finish.

- Thermal forming and milling for applications requiring precision and durability.

Thanks to our advanced machinery and in-depth expertise, we provide customized solutions for a wide range of applications, including insulation, packaging, technical components, and design solutions. At IFG, technology and craftsmanship come together to execute every project precisely according to your specifications.

Our Working Methods: Efficiency and Quality in Every Detail

At IFG, an efficient and structured approach is key. Our process begins with a thorough assessment of your requirements and specifications. Based on this, we develop a solution that perfectly aligns with your objectives.

This is how we create your customized solution:

- Idea and Concept: Every project starts with a great idea. Together with you, we map out the initial concepts, clearly defining your vision and goals.

-

Product Specification: In this phase, the requirements and preferences are detailed. This forms the foundation for the design and provides direction for the further process.

- Design: Our designers transform your ideas into detailed designs, supported by the latest CAD software. This ensures that the design perfectly meets your specific needs.

- Prototype and Validation: If desired, we create a prototype to test and refine the design. This allows us to ensure that the final product meets your expectations both functionally and visually.

- Final Product: With our advanced machinery, we carry out all production processes, from contour cutting to CNC milling, entirely in-house. This gives us full control over both the quality and the lead time. Each product undergoes precise finishing and rigorous quality control before delivery.

Why Choose IFG?

The success of your project depends on the right partner. At IFG, we combine years of experience with innovation and a customer-focused approach. Here are the reasons why we are the ideal choice:

- Full control over the production process: All our work is carried out in-house, resulting in shorter lead times and consistent quality.

- Customization for every client: Thanks to our flexible approach and extensive capabilities, we offer solutions that perfectly match your specific needs.

- Innovation and precision: With the latest technologies and advanced software, we deliver products that meet the highest standards.

Our solutions are tailored to specific customer needs, with a focus on quality, sustainability, and efficiency.

Contact IFG

Do you have a project that requires custom foam processing? Or would you like to learn more about our techniques, applications, and possibilities? At IFG, we are ready to work with you to develop the perfect solution.

With our extensive experience, advanced technology, and customer-focused approach, we provide customized solutions that are fully tailored to your specific needs. From the initial design to delivery, you can rely on craftsmanship, precision, and top-quality results.